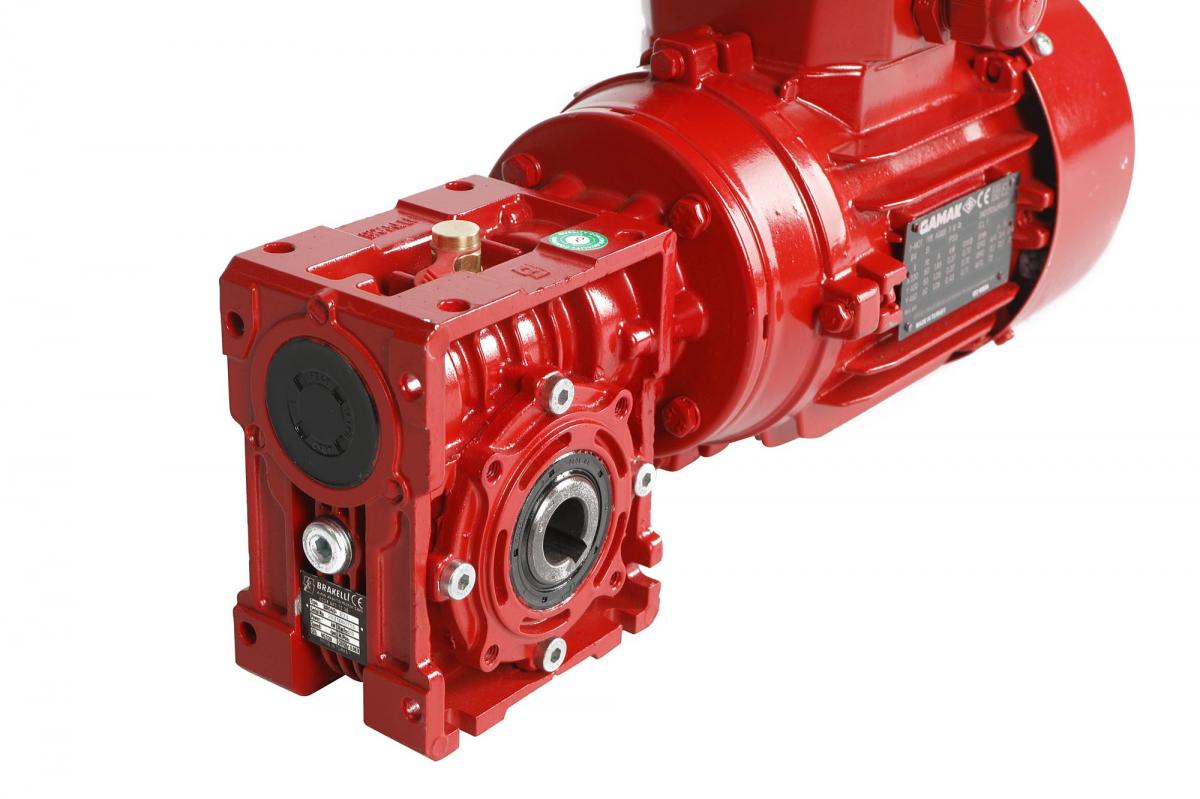

E TYPE

WORM GEAR REDUCERS

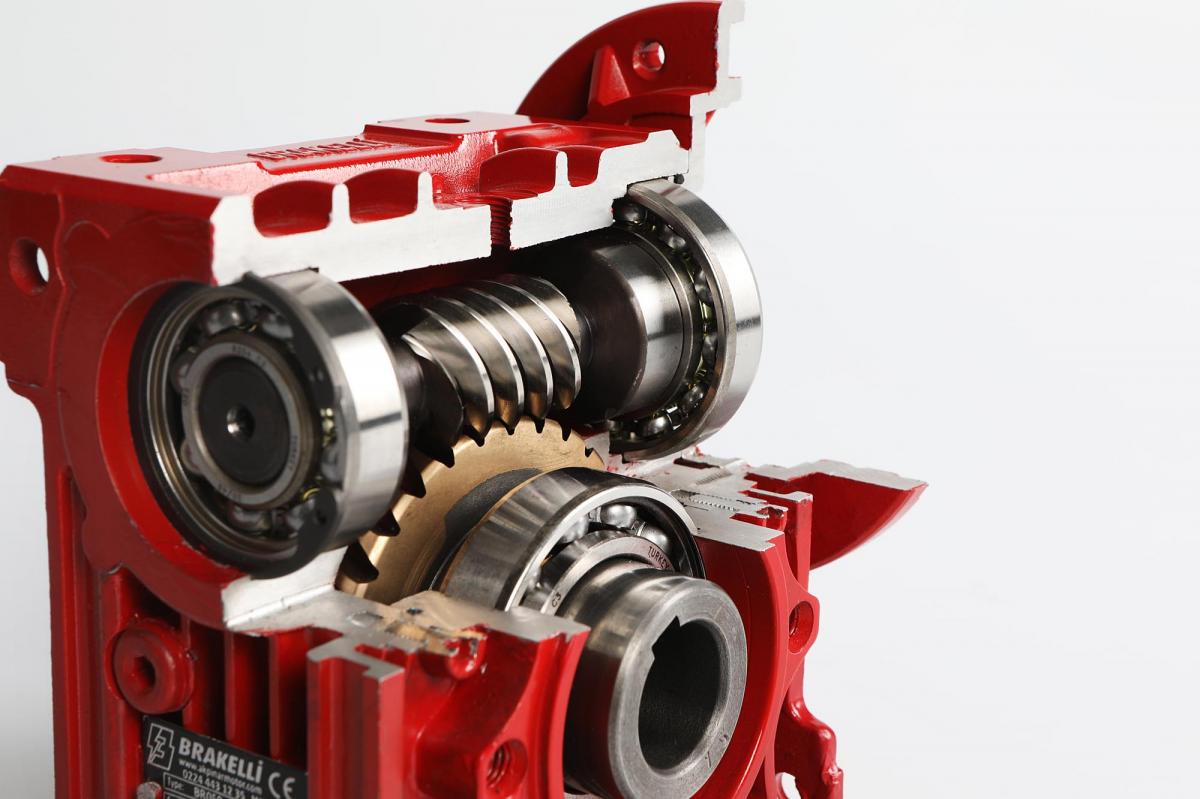

Worm gearboxes are the most widely used gearbox type in industrial applications. There is an angle of 900 between the input and output of the gearbox, which consists of worm screw and worm gear pair. To minimize the friction loss of the worm screw and gear; using special materials to ensure silent and vibration-free operation; we make the grinding process by hardening the worm screw.

OPERATION

Monoblock body design,

Thanks to the worm screw and worm gear in the compact body, it reduces the input speed by the bond ratio and increases the output torque.

ADVANTAGES

- Lower costs

- High performance

- Due to its compact body structure, it takes up little space and is light.

- It has a wide bond range (Bond ratio: 5-100)

- Mounting of engines of different power and speed on a single body

- Belt pulley, sprocket etc. It can be coupled with endless or different types of reducers in order to increase the bond ratio or obtain more torque.

SCOPE OF APPLICATION

- Defense Industry

- Electric Vehicles

- CNC Machining Centers

- Textile Machinery

- Furniture Machinery

- Agricultural Machinery

- Crane Systems

- Conveyor Belt Systems

- Business Machines

- Automation Systems